Hotline Numbers

020-82227376(Mr. Deng)

| Power Supply: | 3p 380V 50-60Hz 9KW |

| Machine Size: | 6950*1600*1898(mm) |

| Max.Labeling Speed: | 120Sheets/min(Size:390*543mm) |

| Speed adjustable: | Numeric setting type |

| Label out-feed Max. Speed: | 60M/min |

| Label out-feed accuracy: | ±0.2mm |

| Label accuracy: | ±0.5mm |

| Sheet paper Max size: | 650mm*650mm |

| Stacker max. height: | 500mm |

| RFID lable Max. width: | 120mm(wet Inlay) |

| RFID lable Max.diameter: | 350mm(wet Inlay) |

| Core Diameter: | 76mm |

| Weight: | 2260Kg |

The above parameters are for reference only. The actual product may vary.

-Place the single wide cardstock material on the right feeding platform. The feeding platform will automatically adjust its height according to the height of the cardstock placed on it.

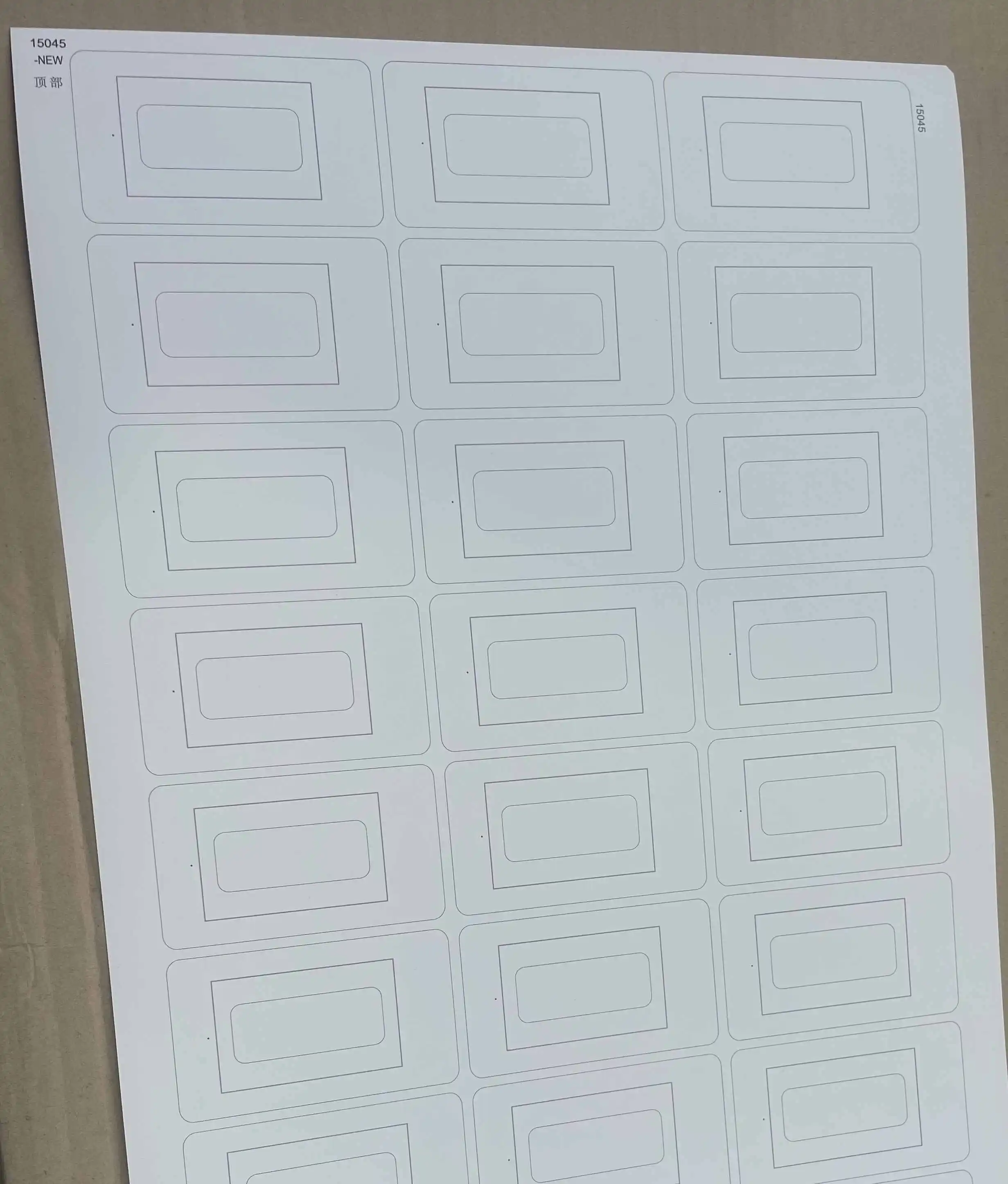

-The suction cup (with vacuum adsorption) picks up a single sheet of card paper and delivers it to the labeling platform. The platform conveyor belt automatically shapes and positions the paper, ensuring the distance between each sheet of paper and preventing paper overlap. Then, it prepares for paper feeding to proceed with labeling.

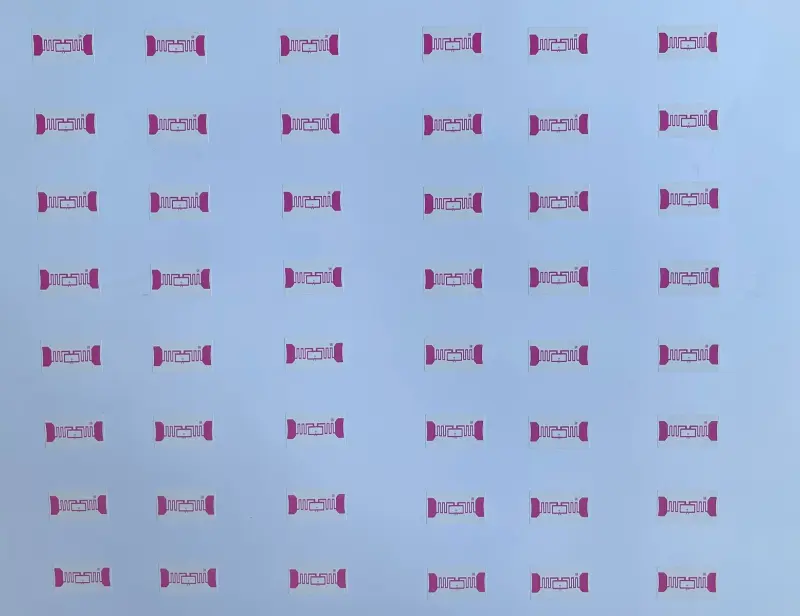

-Each label header is responsible for labeling each row of labels. The number of labels and the spacing are set through the touch screen, ensuring that each row of labels is labeled precisely.

-After the labeling is completed, each sheet of card paper enters the receiving tray. The receiving tray automatically descends. Once a certain number of card papers have been received, a prompt will be given to remove the completed labeled papers. Then, the receiving tray automatically rises to continue receiving more materials.

Questions?

CLS technical consultants have the answer for you!

020-82227376

cls@clsgd.com